The F.C. Bond Ball Mill is a small universal laboratory mill used in calculating the grindability of all ores. GRINDASILITY IS TIM NUMBER OF NET GRAMS OF SCREEN

25 pages

486 KB – 25 Pages

PAGE – 1 ============

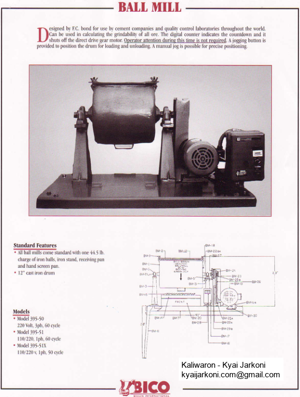

BAI,I, MII,I,1\e\itsnrd h\ tl. hund fur rAe b\ ccnrcnt Lunrpanies and qurliq control ldorutodes lhroughout dtc rofld.I lt”.l]r hc usd In (. rul,rtift lhr grindrhr||h 0f all ofc The digital cornter indicales the counldo$n end it.l-., slrul’ nff rlrc drfLrr dri\r ilr mrlu.lrncmn)f attcnti0n durins this time js not reouired. A joging bltlon islrolidcd to positioo lhc drun ior beding md urloadirg. A rlr.tnudljog is possible fofpfecise posilioningStandard Features. .\ll ball milk come nandard$ith ooe {4 5 lb.ch.ugc 0f lon hdls. ifon slmd, fcccivingtmlUld hmd screen pm.. lil cir-sl ifon dru lModelsl’ii ilqi so220 \bll, Jph.60 oclc. Modell95-i1110,’120. 1th. 60 crcle. l\ odel J9t 5I\ll0,220!.1ph,50qclc

PAGE – 2 ============

F.C. BOND BICO BALL MILLThe F.C. Bond Ball Mill is a small universal laboratory mill used in calculating thegrindability of all ores.GRINDASILITY IS TIM NUMBER OF NET GRAMS OF SCREEN IJNDERSZEPRODUCED PER REVOLUTION.This Ball Mill can be used continuously or it can be used for any numbq ofrcvolutions,accoding to the type of grind desired. For instance, the Frcd C. Bond Grindabiliry Tests w•remade in the Bico Mill rurming at 70 revolutions per minute, with a charge of285 iron ballsranging in size from 3/4 inch to 1-1l2 inch in diameter, and weighing approKimately 20,125grams. 700 CC ofminus 6 mesh, stage crushed, dry feed was used and the circulation loadmaintain•d constant at 250% by adjusting the number of revolutions for each grinding period.BALL CHARGE DETERMINATIONBecause ofvaxiations in ball size, no exact number ofballs ofeach size can be specified.The ball charge is prepared by starting with 285 balls, consisting of approximately equal weightsofvarious size balls. These sizes include: 3/4 incbr T 18 irrch, 1 inch, 1-114 inch and 1-112inch.. about 400 grams ofeach size. With 285 balls always present, some balls ofone size areremoved ard replaced with the next size of larger or smaller balls.This is continued until the total rveight is at close to 20,125 grams as possible, makingthe last adjustment with the smallest size of balls. Do not remove all the balls of any one size.Once a suitable grinding charge is prepared from one grade ofballs, count and note the numberofballs of each size.Other batches ofthe same grade can be started using this count, and firther adjusted ifnecessary. It is IMPORTANT to ietain the “one for one” rutio while adjusting the final weightto maintain the DroDer ball count.continued. ..

PAGE – 3 ============

OPERATING INSTRUCTIONSCoruect the powet supply to the contol box. Wircs arc protuding for easy aonnection.Make sule all circuit breake$ arc of to avoid sev•re electical shock.This machine is equipped $r’ith an automatic counter. To set the count•r, press the buttonto the desired numb•r ofrcvolutions. The switch has two positions, “RUN” for normal use, and”JOG” to move tho drum to a desired positiotr (for emptyns),To load the drum, “JOG” thc drum Asning until it faces upwaid. Rsrnove the cover andgasket, Insert the sample atrd ball charge into the drum. Replace th• gasket and cov•r. Set thenumbcr ofrevolutions you desirc on the counter and start the motor by pushing the strrt contol.The machine will stop automatically when tle number ofrevolutions is reached. Again,us• the “JOG” button to positio[ the opening of the drum upwad towards the ceiling. Now,remove.the cover atrd gaskot. Agai!. ‘JOG” the opening of the drum towards the receiving panso the sample and balls can discharye iltto the reccivilg pan.

PAGE – 4 ============

F. c. BOND BALL MILL CEARGEWe fird that the question ofcolrert bsll chargc arises oft•u and is still yery debatable.Back in 1960, Mr. Bond himself recommended thc chargc dcscribed;43 batle – 1-ll2 inch (1.45)67 balls – 1-ll4 iuch (1.17)10 balls – 1 inch (1.00)7l balls – 3/4 inch (.75)94balls – 5/8 inch (.61)285 BALLS Total wt. =rDx.44.5lbs.Mr. Bond himsclf admittcd tllat it is very difrcult to spwifr a given number ofballs ofeach weight, and in oul most receni conglondlncr with Mr. Bon4 ha l•coDtrl•ad•d a chsrgeexcluding the 5/8 ittch (.61) balls. Becausc ofthis, Bico Inc. o(pcrimrntdly came up with thcfollowing figure for a cbrrge:25 balls – 1-ll2 inah (1.50)39 balls – l-1l4 inch (1.25)60 balls – I itrch 0.00)68 balls – 7/8 inch (.875)93 balb- 3/4 inc.h ( .75)285 b&llr Totrt wL = apr. 44.5lbs.We irclude scveral exta balls of cach size so that tbe charge cau b• manipulat•d to resultin the 20,125 gm total n’it! 285 ba!s.

PAGE – 5 ============

BICO INc; F. C. BOND BALL.MIL,LSPARE PARTSPLEASE SPECTtrY SERIAL NUMEER WEEN ORI’f,RING(.ATAI.OG # NN-SCf,r?ITON I trS/I(GDruD, with Shaffs (Pleasc speciS SA.I)CovcrHaagsrTable with LegsPillow BlockAsb•stos Gasks,t50IIz Dgital Comter/Jogging Swibh60 Ilz Digitsl CounlF4ogging SfitcltCouDter BrackctCourtlr hrorPao with Ss’reca ard Rccaivitrg PaltChEge ofBaUsChain CuardChain, onc l•agth = 29 inchcsConnecting link foi 60 I{Z opaetiodOffsct link for 50IZ opcrdionShaft Key*** Sprockets arc avsilable and quoted upon rcqucat. (S/N ed IU rcquired).BM-IBM-2BM.3BM4NBM-9BM-I2BM-134BM-138BM-13CBM.13DBM.I4DO8M.15BM-23BM-26BM-294BM.298BM-32n3/521lt513/6109/50tl.4.3t.19t450n231t.5u.4ll.4t/.4

PAGE – 6 ============

1.TO TURN DRUII BY}IA ND.-_2. TUR N END OF SHAETW TH W RE NCH,(-r,i oT o R c0vER BEHTNDcoNT ROL PA NE L)”‘lRed8$. o8it’fi’88l’J’AiPufl F oNANDLE AND PUtL IOIiARDS YOU.!,PESS ;HESE 4 LOWEP BU_TO\S N ‘IURN -O SET N LI,lBERABOVE EACH. _ SETSWITCH ON RUN. – PRESS SIART BUTTON-f/IACHINE WILL SHUT OFF A FTER NUN4BER 0F TURNS COMPLETE., TO JOG N4ACHlNE’ I. P.’T SWITCH ON JOG. 2. KEEP PRESSINGSTART BUTTON 0N AND OFF UNTIL DESIRED POSlTl0N-.’lS IRE ACHE D,amzz

PAGE – 8 ============

W]RING DIAGR.AM TOR BAI,], MII50 cYclB 220 VOLT3f\nNsFa.rn eR f&lLJ To ,1*SiAzT ST0P PbI to 9 J(^PI To Jo6 4-Jcs ptsNCI-N.c- Ca/rt4 kFLav Ir3I-rIt\xI’YI,||SF arta e&.X.l To PB?’i.- .i ._: -,1 r.o til3 fE Soc 2.q TD A(r 13L fo –t’ttZ r0 c|t4 TO PbToTO’rDCz ta4e I cCtr, IcaC7(od,.lTgaCr ao Au\ E4aZ ro }rt- CCc3 To A4r 62ca to SAc5 ro -.6’rb Czc’t lo x2-cRlBc? fD czt A9,rerE ea ra y2B ?o q5l3 Tc PB+tl rt 3t’ll lo cr.tl6r r0 sB-ciLL Ta CISEr soe5A roUu-Nrea cr,q cu rT

PAGE – 9 ============

C)ZoOc;l;lit,Yls;q5toITzooFa))ztaLrlIIOC)l.rsacr= —z_;; .rr ;f co t/)=>_m m !,.)m()o-trlt:oF9-a’:3ua;-,.: ]ai 1i31? i;6 jo.LN()Lr-i{