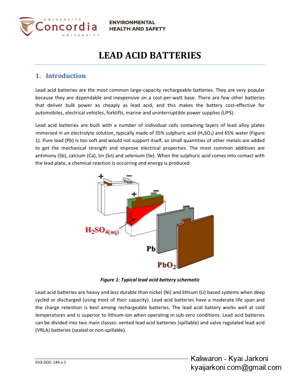

When the sulphuric acid comes into contact with the lead plate, a chemical reaction is occurring and energy is produced. Figure 1: Typical lead acid battery

115 KB – 18 Pages

PAGE – 1 ============

EHS – DOC – 146 v.1 1 / 18 LEAD ACID BATTER IES 1. Introduction Lead acid batteries are the most common large – capacity rechargeable batteries. They are very popular because they are dependable and inexpensive on a cost – per – watt base. There are few other batteries that deliver bulk power as cheaply as lead acid, and thi s makes the battery cost – effective for automobiles, electrical vehicles , forklifts, marine and uninterruptible power supplies (UPS). Lead acid batteries are built with a number of individual cells containing layers of lead alloy plates immersed in an elect rolyte solution, typically made of 35% sulphuric acid (H 2 SO 4 ) and 65% water (Figure 1) . Pure lead (Pb) is too soft and would not support itself, so small quantities of other metals are added to get the mechanical strength and improve electrical properties. The most common additives are antimony (Sb) , calcium (Ca) , tin (Sn) and selenium (Se) . When the sulphuric acid comes into contact with the lead plate, a chemical reaction is occurring and energy is produced. Figure 1: Typical lead acid battery schemati c Lead acid batteries are heavy and less durable than nickel (Ni) and lithium (Li) based systems when deep cycled or discharged (using most of their capacity) . Lead acid batteries have a moderate life span and the charge retention is best among rechargeabl e batteries. The lead acid battery works well at cold temperatures and is superior to lithium – ion when operating in sub – zero conditions. Lead acid batteries can be divided into two main classes: vented lead acid batteries (spillable) and valve regulated lead acid ( VRLA) batteries ( sealed or non – spillable).

PAGE – 2 ============

EHS – DOC – 146 v.1 2 / 18 2. Vented Lead Acid Batteries 2.1 Hazards their conspicuous use of liquid electrolyte (Figure 2) . These batteries have a negative and a positive terminal on their top or sides along with vent caps on their top. The purpose of the vent caps is to allow for the escape of gases formed, hydrogen and oxygen, when the battery is charging. During normal ope ration, water is lost due to evaporation. In addition, the vent caps allow water and acid levels of the battery to be checked during maintenance. Figure 2: Typical vented lead acid battery schematic The main haza rds associated with lead acid batteries ar e: 1) Chemical (corrosive) hazards 2) Risk of fire or explosion 3) Electrical shocks 4) Ergonomic hazards related to their heavy weight 5) Transportation hazards Acid burns to the face and eyes comprise about 50% of injuries related to the use of lead acid batteries. The remaining injuries were mostly due to lifting or dropping batteries as they are quite heavy. 2.2 Chemical Hazards 2.2.1 Sulphuric Acid Lead acid batteries are usually filled with an electrolyte solution containing sulphuric acid. This is a very corrosive chemical ( pH<2) which can permanently damage the eyes and produce serious chemical burns to the skin. Sulphuric acid is also poisonous , if swallowed. The lead alloys found in batteries are also harmful to humans and can also seriously damage the environment. When wo rking with battery acid, the following precautions must be taken:

PAGE - 3 ============

EHS - DOC - 146 v.1 3 / 18 Wear the proper personal protective equipment (PPE), specifically splash - proof goggles, acid - resistant lab coat or apron , safety shoes and rubber gloves. A face shield must also be worn when refilling batteries with electrolytes. Know where the emergency showers and emergency eyewash stations are located; they must be located near lead acid battery storage and charging areas. Slowly pour concentrated acid into water; do not add water to acid. (warning: electrolyte will become hot; do not close battery vents until electrolyte has cooled down) Use non - metallic containers and funnels. Ensure neutraliz ers (e.g. baking soda) are available for immediate use. Use extreme care to avoid spilling or spl ashing the sulphuric acid solution Table 1: Characteristics lead acid battery electrolyte (35% H 2 SO 4 / 65% water) Health Risks (WHMIS 2015) color clear odor sharp, pungent pH 1 to 2 Boiling point 95 - 115°C LC 50 (rat) 375 mg/m 3 LD 50 (oral, rat) 2140 mg/kg 2.2.2 Electrolyte Spill In the event of a minor electrolyte spill (Figure 3) , consult the appropriate Safety Data Sheet (SDS) for electrolyte spill containment, clean - up and disposal details. Always ensure to wear adequate protective clothing (goggles, closed shoes and gloves) during clean - up of spills. In case of a small electrolyte spilled , you should: Contain the spill with absorbents such as universal pads, hazmat pads, sand, earth or vermiculite. Remove the absorbents once it has soaked up the acid/ electrolyte. Clean up spilled acid safely with an acid neutralizer and then with large volumes of water to rinse the area. Safely dispose of any contaminated material as chemical waste by contacting hazard ouswaste@concordia.ca Advise your sup ervisor and complete an Injury / Near - Miss Report ( EHS - FORM - 042) . In the event of a large acid electrolyte spill : 1. Advise and warn co - workers. 2. Evacu ate the area immediately. 3. Restrict the access to the area. 4. Notify Security at X 3717 or ( 514 ) 848 - 3717 , providing them with the following information:

PAGE - 4 ============

EHS - DOC - 146 v.1 4 / 18 a. Location of the spill b. Name of hazardous material c. Quantity involved d. Related health risks and precautions to be taken 5. Provide the Safety Data Sheets (SDS) or appropriate documentation. Figure 3: Picking up a small battery electrolyte spill 2.2.3 First - Aid M easures In the event of exposure with sulphuric acid, Security must be immediately contacted at X3717 . Followin g an exposure, a n Injury/Near - Miss Report ( EHS - FORM - 042 ) must be sent to EHS. i. Contact with skin Flush the contaminated area, as quickly as possible, with gently flowing lukewarm water for at least 30 minutes; if any irritation persists, repeat flushing Under running water, remove contaminated clothing, shoes and other leather goods (e.g., watchbands, belts); discard any contaminated clothing, shoes, etc. Seek medical treatment if requir ed. ii. Contact with eyes Immediately flush the contaminated eye(s) with gently flowing lukewarm water for at least 30 minutes while holding the eyelid(s) open. If any irritation persists, repeat flushing and seek medical treatment immediately 2.2.4 Bad Odors Over - c harging a vented lead acid battery can produce hydrogen sulfide (H 2 S). The gas is colorless, very poisonous, flammable and has the odor of rotten eggs. Being heavier than air, the gas accumulates at the bottom of poorly ventilated spaces. Although noticeable at first (olfactory detection between 0.001 - 0.13 ppm ), the sense of smell deadens the sensation with time and potential victims may be unaware of its presence. When the odor is detected, one must turn off the charger, vent the facility and stay outside until the odor disappears . Refer to S ection 2.4.2 for proper chargi ng safety tips.

PAGE - 5 ============

EHS - DOC - 146 v.1 5 / 18 2.3 Fire & Explosion Hazards 2.3.1 Hydrogen Gas Vented lead acid batteries vent little or no gas during discharge. However, w hen they are being charged , they can produce explosive mixtures of hydrogen (H 2 ) and oxygen (O 2 ) gases, which often contain a mist of sulphuric acid . Hydrogen gas is colorless, odorless, lighter than air and highly flammable. Oxygen is an oxidizer than can promote the burning or explosion of flammable and combustible materials. The mixture of two parts hydrogen to one part oxyge n produc ed is perfect for an explosion. If area ventilation is poor or the charging batteries enclosed , the escaping hydrogen creates an explosive atmosphere around the battery. In sealed rooms with poor ventilation, hydrogen may accumulate near the ceilin g. Hydrogen must not be allowed to accumulate in concentrations greater than 1% of the volume of air in a space (the lower explosive limit [LEL] for hydrogen is 4% and the upper explosive limit [UEL] is 75%). A hydrogen (H 2 ) detector (Figure 4) at ceiling leve l must be installed in rooms where vented acid lead batteries are being charged . F igure 4: Different types of hydrogen detectors 2.3.2 Storage Stored lead acid batteries create no heat. High ambient temperatures will short en the storage life of all lead acid batteries. Vented lead acid batt eries would normally be stored with shipping (protecting) plugs installed, in which case they release no gas. With shipping plugs removed, vented lead acid batteries can give off minor amounts of hydrogen and oxygen due to normal evaporation of water, depending upon the amount of ambient heat and air humidity. Vented lead acid batteries should be installed in dedicated battery rooms, but may share the same room as the equipment they support (such as a UPS system). Such r ooms must be physically separated from other areas, dev oid of localized heat sources and have doors and/or partitions designed to meet the required fire resistance rating for the application. Vented l ead - acid storage and charging areas should be posted wit h appropriate signage (Figure 5) , such as: the room contains energized battery systems;

PAGE - 6 ============

EHS - DOC - 146 v.1 6 / 18 the room contains energized electrical circuits; the battery electrolyte solutions are corrosive liquids; hydrogen gas is generated. Figure 5: Examples of lead - acid batter y danger signs (ANSI and OSHA respectively ) Storage of vented lead acid batteries is covered under th e National Fire Protection Association ( NFPA ) 1 Fire Code (section 52) and the International Fire Code (IFC , section 608 ). However, the IFC applies o nly to battery systems with more than 50 gallons (189.3L) of electrolyte , while t he NFPA 1 applies to battery systems with more than 50 gallons (189.3L) of electroly te in a room without sprinklers or 100 gallons (378.5L) of electrolyte in a room with sprin klers. The NFPA 1 and IFC state that , for vented lead acid and VRLA batteries, the ventilation system shall be designed to limit the maximum concentration of hydrogen to 1% of the total volume of the room or that a continuous ventilation shall be provided at a rate of not less than 1 cubic foot per minute per square foot [1ft 3 /min/ft 2 or 0.0051 m 3 /(s . m 2 )] of floor area of the room. Other standards that are often used to determine proper ventilation include, but are not limited to: National Fire Protection Association (NFPA) 76: suggests that any battery room exhaust fan capacity in Cubic Feet Minute (CFM) should be in the room area (in sq. ft.). American Society of Heating, Refrigerating and Air - Conditioning Engineers ( ASHRAE ) 62: recommends 1 CFM per char ging ampere to be provided, but not less than 6 air changes per hour. While all batteries will operate within a fairly wide temperature range, the life expectancy of a battery can be severely shortened at high temperatures. The optimum temperature for air around a stationary battery is 22° + / - 5°C. The reduction of a vented lead acid battery life from heat above the recommended temperature is about 2.5% per each 1°C. As these batteries contain an electrolyte in the liquid form, special spill containment systems (e.g. spill tray) ( F igure 6 ) and the presence of an acid - neutralizing spill kit are required (NFPA 1 and IFC). An ABC - type fire extinguisher must also be present in these rooms.

PAGE - 8 ============

EHS - DOC - 146 v.1 8 / 18 When working on batteries, workers must not wear items of jewellery (e.g. watches, rings) as they may short out the terminals. Use an appropriate strap or cradle to carry batteries. Never carry them by their terminal posts. 2.4.2 Charging Batteries The following precautions shall be taken when charging or recharging vented lead acid batteries: Make sure that you have been trained how to charge the battery; check battery charging which electrolyses some of the water, emitting hydrogen and oxygen (outgassing). Check that t he battery ventilation holes are clean to allow the hydrogen gas to escape and prevent the battery from exploding. If the battery is not maintenance - free, remove the filler Before recharging a battery, check the electrolyte level; if the electrolyte is covering the top of the plates, do not add more water. If the plates are not fully covered, fill to the designated level before charging and top up after charging if necessary. Never add electrolyte during charging. Fill batteries with distilled or deionized water, not tap water. Wear safety gloves, chemical apron, goggles and face shield while removing caps and filling up batteries with water. Make sure the power is shut off at the c harger before connecting or removing the cable negative ( - ) lead to the negative terminal. Charge batteries in a properly ventilated area. Do not smoke, carry out ho t work (e.g. welding, brazing, grinding), or use a mobile phone in the charging area. Ensure there is an ABC - type fire extinguisher nearby Do not allow batteries to freeze. A discharged battery freezes sooner than one that is fully charged. Never charge a frozen battery. If the battery has been outside in cold weather, let it warm up to room temperature before charging. Do not charge at temperatures above 49°C (120°F). Formation of gas bubbles in a flooded lead acid cell indicates that the battery is reachi ng full state - of - charge (hydrogen on negative plate and oxygen on positive plate). Allow a vented battery to stand for at least 20 minutes after disconnecting it from the charger. Carefully top up the electrolyte with distilled or deionized water to the ma recommended level. 2.5 Ergonomic Hazards Most lead acid batteries are heavy; the average weig ht for a car battery is 17 kg (39 lb s ) and more than half of the weight is lead. Industrial batteries used to power mobile equipment can weigh upwards of 680 kg ( 1,500 lbs ) . Due to the heavy weight of these types of batteries, correct lifting, handling and transportation procedures should be followed to avoid any injuries:

PAGE - 9 ============

EHS - DOC - 146 v.1 9 / 18 Get your body as close as possible to the battery before lifting or lowering it . Bend your knees slightly before lifting or lowering the battery . Do not lift a heavy battery alone ask for help from a co - worker or use a lifting device . Use the battery carry straps to lift or carry a battery; battery carrier straps can be purchased from ba ttery suppliers (Figure 8 ) . Figure 8 : Carrier strap for lead acid battery Carry the battery close to your body and at the centre of your body . Do not twist; first lift the battery and then move your feet to move the battery . Watch for slippery floors and obstructions as you move . When carrying the battery, avoid tilting it and wear appropriate protecting clothing (lab coat, smock or apron). 2.6 Battery Powered Equipment 2.6.1 Types of Lead Acid Batteries Lead acid batteries are the most often used to power vehicles and other motorized equipment. Lead acid batteries with a conventional charger are the predominant technology option, due to their low cost, reliability and well - established supply chain . The battery most common to everyone is the engine starting bat tery. The starter battery is designed to crank an engine with a momentary high - power load lasting a second or so . T hese batteries are most commonly 12 volt but can be found in 6 volt in older equipment and 24 volt in aircraft starting applications. The se batteries are of different shapes and sizes but the rule of thumb is, the bigger the battery, the more power it will deliver. The other type of lead acid batteries found within motorized equipment is known as deep cycle and/or traction batteries . M arine applications, golf carts , fork lift trucks , ice resurfacers and other electric vehicles use deep cycle batteries which are designed to be completely discharged before recharging (Figure 9).

PAGE - 10 ============

EHS - DOC - 146 v.1 10 / 18 Figure 9: Examples of vented lead acid powered equipment or veh icles; from left t o right: forklift, scissor lift and ice resurfacer T hicker and stronger or solid plate grids are used for deep cycling applications (Figure 10 ) because charging causes excessive heat which can warp the plates. Thicker plates increase the longevity and cycle life of deep - cycle batteries as each time the battery is discharged and recharged , a small amount of active m aterial is shed from the plates. A starter battery cannot be swapped with a deep - cycle battery or vice versa . Figure 10 : Typical plates found in starting (left) and deep - cycle (right) batteries 2.6.2 Facilities Requirements Facilities that are considering switching from fossil fuels to battery powered equipment must consider a variety of construction and operational issues beyond equipment selection. There is no direct legislative obligation that clearly guides indoor battery use or charging for electrical equipment. It is left with each owner to ensure compliance specific to their bat tery type and equipment design. Howe ver, as ind icated in previous sections , vented lead acid batteries may produce flammable and toxic gases during recharging process that require to be vented . Recharging equipment powered by such batteries in areas like basements or other places where ventilation is poor or re circulated into living quarters should be forbidden. For both new and retrofit construction , areas designated to recharge vented lead acid battery - powered vehicles or equipment must ha ve the followings : ventilation system must be designed to provide removal of fumes and excess heat from area directly above charging batteries;

PAGE - 11 ============

EHS - DOC - 146 v.1 11 / 18 v entilation equipment shou ld be of explosion proof design; ceilings in battery charging rooms be flat as to not allow pockets of gas to accumulate ; lighting be fixed to the wall or suspended at more than 50cm from the ceiling, but not above the charging unit ; all fixtures should be closed so that gas cannot accumulate ; to avoid water contact chargers should be mounted off of the floor 1.2m ; equipment and other matter should be kept 1.2m from charger ; d epending on the size of battery, an emergency eye wash station may be required . Equipment manufacturers will usually provide guidelines and ways to determine room ventilation requirements for their equipment. The following serves as an example of calculation s used for an ice resurfacer room design ; this may not be valid for all vented lead acid powered equipment : Determining hydrogen production (H) : H = .00027 x F x C F = finish charging rate C = number of cells being recharged Determining ventilation (V) requirement: V = R X P / H X 60 V = Ventilation required R = Room in cu. feet P = Maximum % of hydrogen allowed = .01 H = Total hydrogen produced per hour Determini ng fan requirement: Fan size = R / V R = Room in cu. feet V = Ventilation required P recautions must be ta ken even when using vented lead acid battery - powered equipment , mainly when recharging them. Facilities have to be aware of these potential risks when pu rchasing this type of battery - powered equipment. Equipment powered by other types of batteries (e.g. lithium or sealed lead acid) , which may be more expensive on purchase but require less maintenance and fa cility operation issues, should be considered at the time of purchase . 2.7 Transportation Vented lead acid batteries cannot be shipped as limited quantities or con sumer commodities. Therefore, they must be shipped in full compliance with the Transportation of Dangerous Goods (TGD) Act . Full compliance requires:

115 KB – 18 Pages