That same dedication toward performance is put into the soles, heels, toplifts, and sheet products that are produced specifically for the outdoor and casual footwear

450 KB – 108 Pages

PAGE – 3 ============

Style NumberStyle Name Page SOLID SOLES 100Montagna 12100Montagna Heel 12109Logger13127Athletic 13132Montagna 14134ARTechnical Lug 14148Kletterlift 15171CMarmaloda 15232Mini-Lug 16268Dress 16269Westerner 17342CMini Ripple 18430Oil-Resisting 19430Oil-Resisting Heel 19417KFlat 20625KPredator 20669KSSkull 21700Tygum 227335Brown Cork (Core) Heel 22700V-Bar (Washer) Heel 22Q732Freestone 23885KNew Boulder 231014Teton 24 1030Izalco 24 1136Roccia 251149Montagna 251249Mister Tank 261275Olympia 261276Sierra 271286Tacoma Logger 271318Alpha+281328Elvis 281330Newporter 291374Baltimore Wide 291375BiÞ da301442Friedrich 311443Zegama 321474SZegama 331685Mombello 332074New York 342055SEton Sole 352055SEton Heel 352094Lienz 362900Acqua 37ARCTIC GRIP S1219Brush Tap half Sole 40S1219Brush Toplift 40INDEXStyle NumberStyle Name Page ARCTIC GRIP (con tinued)S1244Yellow 41S1319Christy Flat 41MIDSOLES7500Midsole 44BLOWN SOLES 377KChristy 47516K/516NBLong Haul 48528KRoccia Newß ex49810KBologna 501012Silvato 51 S1559Ripple 51 1705Stowe 521716Oxford 521743WBologna 531752Stockbridge 531757Middlebury 541758Stalker 542021Casual 552060Sport 552062Olympic 56950BChristy Camp Moc 562070Scooter 57984KScooter 572345Line-Lite 582602Desert Boot 584007Basketweave 594014Cristy 59HALF SOLES 705Tygum 62700Tygum Heel 622332Lug 625722 / 5723Lug Heel 622336Tapered 635350 / 5351Top Tacco 632340Explosion 635340Explosion Toplift 632341Raptor 645341Raptor Toplift 642724Oil-Resisting 64430Oil-Resisting Heel 642324Mirror 655324Mirror 652725Fine Line 652726Fine Line 652028Richard 66 3349Marzia 66Style NumberStyle Name Page HEELS100Montagna (Washer) 69430Oil-Resisting (Washer) 69438Cowboy (Washer) 70 468Comfort Cushion (Core) 70 700V-Bar (Washer) 71700CV-Bar Elongated (Washer) 717335Brown Cork (Core) 71TOPLIFTS 516KHLong Haul 74 5324Mirror 74 5340Explosion 74 5341Raptor 74 5350Top Tacco 755351Top Tacco 755362Boston 755363Boston 755722Lug 76 5723Lug 76 PROTECTIVE SOLING 2673Protania 797673Protania 797373Protania 80ROCK CLIMBING 7130New Boulder 837507XS Grip 837509Grip Marchiata 847509XS Flash 847510Grip 857520XS Grip 2 867530XS Edge 86SHEETS650Silvano 897106Gum Crepe Sheet 897120XS City Sheet 907166QToplift 907170Lisk 917175Cherry 917279Dupla 927663Tequilgemma 928102Morß ex¨ Pyramid938102Morß ex¨ Suede 938327Woodstock Sheet 948529Sport Utility 948868Super Newß ex958870Newß ex951

PAGE – 4 ============

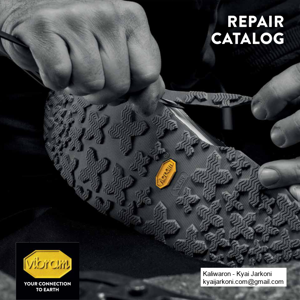

Vibram is the world leader in the production of high performance rubber soles for the sports, industrial, leisure, orthopedic, and repair markets. In 1935 , Italian Alpine Club member Vitale Bramani was part of an expedition on Resica Mountain where six climbers lost their lives, due in part to their low-quality footwear. Upon his return, Bramani had the brilliant idea of prototyping a vulcanized rubber sole with help from the rubber experts at the Pirelli Tire Company. This breakthrough, along with the design of the Carrarmato Sole, revolutionized mountain climbing and the footwear world. Thus, Vibram was born. The Vibram name is an acronym of its founderÕs name, Vitale Bramani . Over the last 75 years, Vibram has been committed to developing an extensive range of high-performance soling products for a wide variety of activities and lifestyles. Thanks to ongoing investments in research and development, Vibram has cultivated an international reputation synonymous with quality, performance, and safety . VIBRAM AND REPAIRS Since the mid-1950s, Vibram has also been a leading player in developing products designed for the shoe repair market. Every year, Vibram creates soling products with unique designs and compounds speciÞ cally intended for repairing all types of footwear. Every day, all over the world, thousands of shoemakers put their trust in Vibram products to guarantee the best results for their customers. Vitale Bramani, Italian mountaineer and inventor of the Vibram sole A LEGEND IN EVERY CORNER OF THE WORLD 2

PAGE – 5 ============

Vibram is headquartered in Albizzate, Italy. With corporate o ces in Boston, Massachusetts and production facilities located in North BrookÞ eld, Massachusetts, Vibram has long been recognized as the leader in high performance soles. Vibram soles are used in extreme conditions such as Þ reÞ ghting, mining, and gas and oil exploration. Vibram soles are engineered to meet the rigorous standards of each industry. That same dedication toward performance is put into the soles, heels, toplifts, and sheet products that are produced speciÞ cally for the outdoor and casual footwear markets. With a global network of production facilities, Vibram takes great pride in our rich history of Made in America; Vibram has been producing soles in the US since 1964 and proudly provides soles to every branch of the US Military. The Vibram Technology Center (VTC) is home to a state-of-the-art research and development center, along with an impressive 12,000 square foot Performance Test Center (PTC). Equipped with climbing walls, ice room, rain simulation, articulating and Þ xed pitch ramps and many other simulated environmental conditions, the PTC is designed and equipped to ensure that our products are thoroughly tested in a variety of conditions. VIBRAM FACILITYNORTH BROOKFIELD, MASSACHUSETTS, USA VIBRAM TECHNOLOGY CENTERUANGZHOU, CHINA VIBRAM HEADQUARTERSALBIZZATE, ITALY 3

PAGE – 6 ============

VIBRAM PERFORMANCE Each new Vibram product is designed for a particul ar use and engineered to meet three objectives: performance, comfort, and durability . The secret to Vibram performance lies in the combination of an innovative, functional design , and the compounds we use. VIBRAM DESIGN Vibram designers are not only experts in appearance , they are technical experts trained to evaluate the characteristics each sole needs to have for its intended use. Vibram designers also work in close collaboration with the Vibram Tester Team . Our designers use the Tester Team’s feedback when designing new product for speciÞ c applications. Designers also collaborate with many biomechanical research institutes in order to identify new lines, volumes, and forms, all with the goal of developing functional and comfortable soles while ensu ring top performance. 4

PAGE – 8 ============

Before Vibram products reach the market, they are all tested us ing strict quality controls. We carry out these tests in our SAT RA- certiÞ ed laboratories by certiÞ ed technicians or directly in the Þ eld by the Vibram Tester Team. Every Vibram sole has to pass three levels of testing to guarantee that the product quality meets the end consumer’s requirements. STAGELABORATORY TESTS Laboratory tests are necessary to determine the physical-mechani cal characteristics of a compound (resistance to slip, abrasion , elasticity, hardness, density, etc.). These tests can be carried out both on soles and sheet samples. density hardness abrasion nominal stress at break elongation at break tear resistance isooctane resistance electrical resistance, antistatic ESD resistance to heat by contact fl ame resistance peeling test Vibram designed and developed DYCO (dynamic compression system). DYCO is a test machine and test method proprietary to Vibram S .p.A. VIBRAM DYCO (dynamic compression system) An innovative cushioning test, to study the cushioning performance of its products, by subjecting them to di erent levels of stress intended to simulate actual use. Cylindrical Drum Abrasion Resistance (ISO 4649) Vibram ® Bio-Abrader Abrasion Resistance Durometer Hardness (ISO 868) Densimeter Density (ISO 2781)DynamometerTensile Stress-Strain (ISO 037) Tear Strength (ISO 034-1) Peeling Lamination strength (EN 12774) Vibram® DycoCushioningTESTED WHERE IT MATTERS 6

PAGE – 9 ============

In addition to extensive laboratory testing, soles are also tested with Vibram In-Vivo test protocols. Vibram In-Vivo test meth ods have been designed and developed to replicate real world usage of Vibram products. Tests for attributes such as “static grip” use the proprietary MAX TRACTION MERIDIAN test protocols. MAX TRACTION MERIDIAN property of Vibram SpA These tests are intended to illustrate the di erences between speciÞ c sole design and compound parings, and allow for the calculation of each pairing’s static coe cient of friction. STAGE 2 N VIVO TESTS STAGEFIELD TESTS The third and Þ nal stage of Vibram testing is Þ eld testing conducted by the Vibram Tester Team. Testing is performed in situations which duplicate both intended and extreme uses. The tester team conducts “blind” tests, taking every product to the limit of its speciÞ c use. During this stage, testers compare the design and compounds of di erent products without the knowledge of the particulars. Once testing is complete, only the best products will be approved for production and launched into the market. TEST CENTER 7

PAGE – 10 ============

CERTIFIED SAFETY AND QUALITY The REACH system – set up by the European Union – is a system for the Registration, Evaluation, Authorization, and restriction of CHemicals for the purpose of improving the safeguarding of human health and the environment. By better identifying the intrinsic properties of chemicals, REACH also contributes to maintaining competition and strengthening the spirit of innovation of the chemical industry in Europe. Vibram is the Þ rst company to work in full compliance with all REACH criteria. Vibram also has a policy to work only with raw material suppliers who comply with these same criteria. REACH SATRA, the leading worldwide research center for footwear technology, research and development, provides its support and expert ise in all stages of product development, from initial research to the evaluation of materials and components, up to and including testing and certiÞ cation, guaranteeing the highest levels of quality. Vibram boasts close daily collaboration with SATRA. The Vibram Technological Center in China and our USA manufacturing facility both have SATRA certiÞ cation. SATRA 8

PAGE – 11 ============

RELIED UPON BY SOME OF THE MOST DEMANDING PROFESSIONALS Vibram proudly provides soles to law enforcement o cers, fi refi ghters, and the military. These individuals place as much trust in their boots as they do in the rest of their gear. Vibram soles enable safe, conÞ dent passage over challenging terrain. They help protect the men and women who keep our country strong. Vibram soles are made for performance and durability. They provid e all-around reliability by guaranteeing maximum traction and superior stability on a variety of terrains, including wet and cold surfaces. Vibram’s Fire & Ice compound is fl ame resistant, and is engineered to withstand extreme temperature ranges. LAW ENFORCEMENTFIREMILITARY 9

450 KB – 108 Pages