The filter cloth is supported by a grooved-rubber drainage belt. When the slurry reaches the vacuum zone, the free liquid is removed and the solids form a cake.

7 pages

248 KB – 7 Pages

PAGE – 2 ============

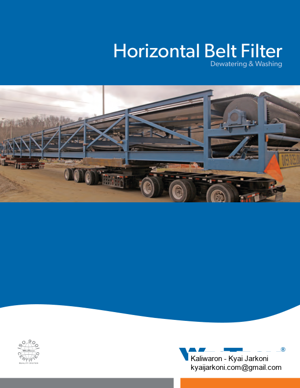

How it Works: The slurry–a mixture of liquid and solids–flows to the Horizontal Belt Filter and is distributed onto the filter cloth. Feed distribution is accomplished via fishtail feeder or flood feed box, depending upon the process stream characteristics. All feed systems are designed to reduce the speed of the slurry and create a uniform distribution across the width of the filter cloth. The filter cloth is supported by a grooved-rubber drainage belt. When the slurry reaches the vacuum zone, the free liquid is removed and the solids form a cake. The liquid–also called filtrate–is pulled through the cake and filter cloth by vacuum into channels in the drainage belt which lead to center drainage holes. From these holes, the filtrate flows to the vacuum box under the drainage belt, before emptying into the filtrate manifold. The filtrate manifold is connected to one or more vacuum filtrate receiver(s). The filtrate in the receiver is discharged or recycled via pump, and the air is fipulledfl from the top of the receiver through the vacuum pump and is vented out of the system. Movement of the drainage belt is facilitated by air slide, water slide, wear belt, or rollers as it travels along the length of the filter. The drainage belt support system is chosen based on the weight of the cake and the utilities that are available at the installation site. The cake can be washed and/or steamed if needed to achieve the desired end product. Cocurrent and countercurrent cake washing systems are available when high-purity cake is required. Cake washing is accomplished with either a flood weir box or a set of spray nozzles, depending on the application. Steam systems can be supplied to improve cake dewatering when targeting critical cake moisture levels. When the cake reaches the end of the Horizontal Belt Filter, the cake separates from the cloth surface as it travels around the discharge roll. An adjustable scraper removes remaining cake. As the cloth and drainage belt travel back to the feed end of the filter, multiple spray bars wash both sides of the cloth and the top side of the drainage belt. This ensures that the cloth and belt can perform optimally. Cloth spray bars are designed to allow change-out of spray nozzles without taking the filter out of service. Tension and alignment of both the cloth and the belt are automatically maintained, facilitating operation of the Horizontal Belt Filter with minimal supervision. All wetted parts can be made from a wide number of materials depending on the process conditions. WesTech Horizontal Belt Filters provide a continuous vacuum on a horizontal plane where slurry is fed onto a ˜lter cloth supported by a traveling drainage belt. Horizontal Belt Filters are especially adaptable to applications where low-cake moisture and/or cake washing is desirable. The WesTech Horizontal Belt Filter outperforms traditional rotary drum, disc, tilting pan, and table ˜lters in throughput and ˜nal cake moisture. WesTech o˚ers a wide range of units from the smallest 0.6 m² pilot ˜lter up to 150 m² in e˚ective ˜ltration area. WesTech will o˛en provide a complete system with vacuum pump, wash water skid, ˜ltrate receiver and ˜ltrate discharge handling equipment.Applications Ł Minerals Concentrate/Tailings Ł Metallurgical Ores Ł Power Wastes Ł Chemical Processing Ł Food Processing Ł Tar Sands Ł Steel Mill Waste Ł Fertilizer Ł Bicarbonate Ł Flue Gas DesulfurizationBenefits Ł High E˜ciency Dewatering Ł Low Cake Moisture Ł Cake Washing – Cocurrent – Countercurrent Features Ł Broad Process Experience Ł Robust Construction Ł Customized Filter for Each Application Ł Easy Maintenance of Wear Belt and Seal Strip Ł Easy to Raise/Lower Vacuum Box Ł No Unnecessary Outtages for Nozzle Replacement

PAGE – 3 ============

Tailored for Your Process The slurry is fed onto the vacuum belt to separate the liquid from the solids. In applications where no further slurry processing is required, this simple, straightforward design works well and is cost e˚ective. Depending on the application, ˜lter cake is dry enough for disposal without further costly drying or can be reused elsewhere in the process. Separated liquid can be reprocessed to improve clarity before it is discharged back into the waterway. The Horizontal Belt Filter has the ˜exibility to meet your process needs. Some applications call for cake washing at some point downstream of the cake formation. In these applications, water–or any other wash liquid–is used to displace the slurry liquid whenever the process requires a cake that is free of removable particulates. Washing can improve the dryness of the cake where a dry cake is critical.A countercurrent cake washing system better utilizes the wash water than a cocurrent system. In this arrangement, ˜lter cake moves in the direction that the belt travels, while cake-washing liquid moves in the opposite direction. For e˚ective washing and separation between ˜ltrate washes, the wash boxes are positioned near the partitions in the vacuum box. The e˝ciency of the wash is de˜ned as a percent of remaining contaminants prior to the wash. Cocurrent Cake Washing Liquid-Solids Separation Countercurrent Washing

PAGE – 4 ============

Filter Cloth Drive Drainage Belt Cloth Tensioner Air/Water Slide Elements of a WesTech Horizontal Belt Filter Feed Dam Roller Feed Box or Fishtail Feeder Wash Box, Spray Bar, or Weir Box Vacuum Manifold Cloth Tracker Cloth Wash Spray System Continuous washing facilitates long cloth life while extending operational time between maintenance shutdowns. Vacuum Box and Bellows The WesTech Horizontal Belt Filter design includes a pneumatically driven vacuum box raising/lowering system which allows for fast and reliable access to the vacuum box for maintenance and cleaning. A quick and easy locking device secures the vacuum box in proper position while not intruding on other parts of the frame.

PAGE – 5 ============

Design Flexibility Belt SupportWesTech o˚ers multiple solutions for belt-supporting systems, based upon di˚ering applications, belt speeds, and resulting cake thickness. Feed Systems WesTech standard feed systems include either a feed box or ˜shtail feeder. Customized feed systems can be designed to meet your applications.*Custom sizes are available on request. WesTech provides a service to choose the correct filter size for your application. Belt Width m2 Filtration Area 0.3 – Meter Belt Width .61.1 1.7 23 0.6 – Meter Belt Width 23567 1.2 – Meter Belt Width 79 111316182.1 – Meter Belt Width 142027344147543.2 – Meter Belt Width 3445 56677889101 4.2 – Meter Belt Width 7489104 119113 148 Welded WesTech Horizontal Belt Filter frames of up to 200 feet in length can be welded prior to shipment. This allows for fiplug and playfl operation, o˚ering the luxury of not having to assemble the ˜lter onsite, and creating an 80% reduction in required assembly time. Frame WesTech o˚ers frame construction of mild steel, stainless steel, and higher-grade alloys as needed to meet application and customer parameters. Frame construction can be monolithic, welded, or bolted. Bolted WesTech Horizontal Belt Filter frames can be bolted for easy, rapid disassembly and reassembly. This construction method enables easy replacement or repairs of the drainage belt and other components. The belt can also be installed from above for locations with access restrictions. Air Box Support WesTech has developed a highly efficient air box design to facilitate equal air distribution underneath the traveling belt. WesTech recommends air cushion whenever the cake thickness is greater than 20-25mm. Water Deck Support When the belt speed is relatively slow and cake thickness is thin, a water slide arrangement can be utilized. Belt Support Deck When cake thickness is less than 20-25mm, WesTech provides sliding strips with wear belts. Roller Support Deck For very thick and/or heavy cakes, WesTech recommends mining rollers.

PAGE – 6 ============

Services and Retro˜ts Lab Testing WesTech o˚ers complete laboratory testing facilities to assist in your project planning. WesTech™s laboratory technicians are specialists in ˜ltration, sedimentation, and ˙otation. Careful testing and analysis of your sample can provide the answers to your most di˝cult process problems, helping to establish design parameters and to size equipment based on bench-scale testing results. Retro˚ts WesTech can retro˜t existing Horizontal Belt Filters with new belts, rollers, pulleys, and support decks to improve your process performance at a lower cost. WesTech can retro˜t all competitors™ Horizontal Belt Filters. Turnkey Solutions WesTech™s design-build team will take responsibility for the full design, equipment supply, installation, and start-up for your most challenging treatment plants. Coupling WesTech™s proven treatment equipment with in-house engineering and construction expertise will allow facility owners and design engineers to focus on the big-picture challenges of the overall project. Field SupportWesTech has responsive and experienced ˜eld service professionals available to come to your site for the installation of parts and equipment, to help you install a part, diagnose a problem, or help with startup of a piece of equipment or an entire plant. WesTech o˚ers ˜eld service technicians and process engineers that understand your equipment and are available 24/7. WesTech has the knowledge and experience to provide support for competitors™ belt ˜lters, as well. PilotingSkid-mounted, pilot-sized units are available for rental or sale to test various process scenarios. The pilot units are typically ready for immediate use.

248 KB – 7 Pages