Description of Jesma belt weigher type VIB/EER: The belt weigher type VIB/EER is built around 2 sets of high precision rollers (A) mounted in a rigid and

119 KB – 7 Pages

PAGE – 1 ============

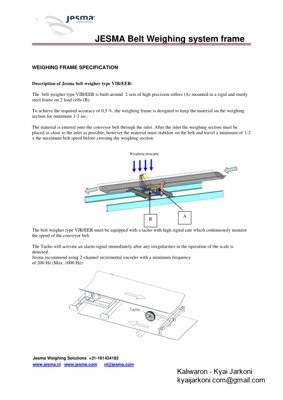

JESMA Belt W eighing system frame WEIGHING FRAME SPECIFICATION Description of Jesma belt weigher type VIB/EER: The belt weigher type VIB/EER is built around 2 sets of high precision rollers (A) mounted in a r igid and sturdy steel frame on 2 load cells (B). To achieve the required accuracy of 0,5 %, the weighing frame is designed to keep the material on the weighing section for minimum 1 – 2 sec. The material is entered onto the conveyor belt through the inlet. After the inlet the weighing section must be placed as close to the inlet as possible, however the material must stabilize on the belt and travel a minimum of 1 – 2 x the maximum belt speed before crossing t he weighing section. Weighing principle The belt weigher type VIB/EER must be equipped with a tacho with high signal rate which continuously monitor the speed of the conveyor belt. The Tacho will activate an alarm signal immediately after any irregularities in the operation of the scale is detected. Jesma recommend using 2 – channel incremental encoder with a minimum frequency of 200 Hz (Max. 1000 Hz) Jesma Weighi ng Solutions +31 – 161434183 www.jesma.nl www.jesma. com [email protected] 1 A B

PAGE – 2 ============

JESMA Belt W eighing system frame Belt weigher type JESMA VIB/EE R – Series For continuous weighing of solids Capacity Accuracy Belt width Belt speed Belt type Belt inclination 1 – 10 00 t/h 0,5% within 20 – 100% of max. capacity 500 – 20 00 mm 0,1 3 m/s Flat, V – shape & Troughed shaped 0° (Material on belt must be stable and not sliding) The belt must be as smooth and thin as possible with same weight per meter in the full length and without holes or leaks. The belt must consist of maximum 2 connections. At full capacity the belt tension should allow 1.5 – 2% slack between the weighing rol lers. This implies that the tensioning section is either a counter – weight or alternatively a spring tension system – The use of clamping screws is not acceptable Conveyor must be straight without radius, and at 50% capacity the rollers may not sway more t han 0.3mm outside a straight line. To achieve the best possible accuracy Jesma recommends that t he stationary idle rollers before and after the weigher must have a mutual distance of min. 0,5m and: a. Are no more than 0.2mm out of balance. b. Are safely anchored. c. Has a common centre line. d. Are adjustable both horizontally and vertically. Jesma Weighi ng Solutions +31 – 161434183 www.jesma.nl www.jesma.com [email protected] 2

PAGE – 3 ============

PENKO Belt W eighing system controller Panel mount version Stainless steel version Integrator, FLEX 2100 BW Part no. 7600A1957 Panel mount 7600A1968 Stainless steel version Features Unsurpassed accuracy with 1600 measurements/second Indication of batch total, grand total, real time load, belt speed Easy calibration, powerful diagnostics Wiring Full Wheatstone bridge with passive connections (6 – wire system). Sense system Passive sense system Minimum bridge resistance 43,75 Ohm @ 5V exc. Number of load cells 1 channel 1 – 8 Load cells 350 Ohm @ 5V exc. or 1 – 16 Load cells 1100 Ohm @ 5V exc. Sensitivity 0.1 – 0.5 µV/V A/D conversion speed 1600 measurements per second Internal resolution 24 Bits (16,777,216 parts). A/D converter type Sigma – Delta, ratio metric, isolated from digital. Display resolution 100,000 divisions max. Display step x1, x2, x5, x10, x50 Decimal comma Selectable between any digits of the display value. Full scale range – 25 mV to +25 mV Excitation voltage 5 VDC (+2.5V and 2.5V with respect to the internal ground). Linearity < 0.001 % of full scale. Offset drift < +/ - 2 ppm/°C Span drift < +/ - 2 ppm/°C Digital filters High performance digital filter 1Hz 10 Hz Overall filter 0 to - 50 dB Calibration methods Dead load and span with up to 8 - point linearization Millivolt calibration G - CAL (Gravity correction) Jesma Weighi ng Solutions +31 - 161434183 www.jesma.nl www.jesma.com [email protected] 3

PAGE - 4 ============

PENKO Belt W eighing system controller Measurement Functions Automatic zero tracking, motion detection, zero, tare, preset tare, net mode, peak hold, valley hold, bar graphs multi range, multi interval Memory Allocation Calibration data Flash, dynamic data in SRAM with battery backup. Real - Time Clock Standard with NiMh battery backup. STANDARD DIGITAL INPUTS (DI) AND DIGITAL OUTPUTS (DO) Digital Inputs 8 DI, optical isolated, 1 common, 18 - 36 VDC, PNP or NPN Input 1 normal or counter input up to 8 kHz Digital Outputs (level cont.) 8 DO isolated PhotoMOS outputs, 2 common Max 36 VDC or A C, 0.5A nominal, 1 A Surge (thermal fuse 0.5A), PNP or NPN OPTION CARD Analog Output 1 Analog output 4 - 20 mA, 0 - 20 mA or 4 - 24 mA ELECTRICAL Power Supply 100 240 VAC 50/60Hz, 15 W max. STANDARD COMMUNICATION PORTS RS 232 Printer, ASCII, TP slave, TP Master, NPV Slave, NPV Master AMI Master, Hostlink Viewteq, Hostlink PLC RS 422 / RS 485 Printer, ASCII,TP slave, TP Master, NPV Slave, NPV Master AMI Master, Hostlink Viewteq, Hostlink PLC Ethernet TCP/IP, UDP layer with PENKO TP protocol USB Printer, ASCII and TP slave CANBUS Buslink - CAN1 port - CAN2 port OPTIONAL COMMUNICATION PROFIBUS DP Profibus GSD File COMMUNICATION SOFTWARE Penko Two Fase Protocol Printer protocol Profibus GSD file for Profibus. With sub D Jesma Weighi ng Solutions +31 - 161434183 www.jesma.nl www.jesma.com [email protected] 4

PAGE - 5 ============

PENKO Belt W eighing system controller TOUCH SCREEN Display type High resolution TFT LCD 640 x 480 pixels, 256 colors High brightness 500 cd/m2 High contrast 350:1 Display functions Completely menu driven with graphical user interface Display Rate Selectable 1, 2, 3, 5, 10 or 25 updates/s Display Filter 0, - 6, - 12, - 18, - 24, - 30, - 36, - 42 and 50 dB Display Filter range Selectable in any range of the display value Display suppression Selectable in any range of the display value Status enunciators Z ero, net, no motion. Display Digits 6 digits with leading zero suppression, selectable height = 18mm or 9 mm. Display operation Operate, configure and calibrate via three interfaces 1 - Front panel, (touch screen) 2 - RS 232 3 - Ethernet Touch screen Glass screen, 2 mm resistive type with protective film on front Display size 5.7 inch, (145 mm) Display material Front foil PET 175 u ENVIRONMENTAL Operating Temp - 10°C to +40°C [14°F to 104°F] Storage Temp - 20°C to +70°C [ - 4°F to 158°F] Relative Humidity 40 90% non - condensing. OPTIONS/ ACCESSORIES Communications PROFIBUS DP Profibus GSD File Option card Analog Output 1 analog output 4 - 20 mA, 0 - 20 mA or 4 - 24 mA Jesma Weighi ng Solutions +31 - 161434183 www.jesma.nl www.jesma.com [email protected] 5

PAGE - 6 ============

PENKO Belt W eighing system controller Stainless steel version Stainless steel mount housing Material housing Stainless steel Dimensions front: W x H x D 240 x 180 x 70 mm Dimensions housing: W x H x D 280 x 200 x 70 mm (including nuts and bracket) Weight approx. 2300 g Protection IP 65 Jesma Weighi ng Solutions +31 - 161434183 www.jesma.nl www.jesma.com [email protected]

119 KB – 7 Pages