Sep 4, 2012 — complete the task of rigging a chain to attach the frame of the conveyor to the lifting eye on the excavator bucket – when.

211 KB – 8 Pages

PAGE – 1 ============

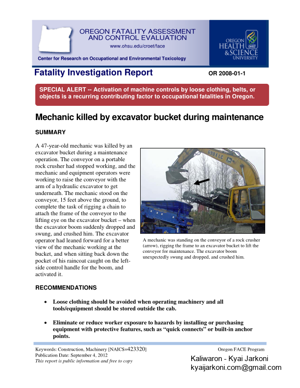

Keywords: Construction, Machinery [NAICS= 423320] Oregon FACE Program Publication Date : September 4, 2012 OR 2008 -01-1 This report is public information and free to copy Page 1 OREGON FATALITY ASSESSMENT AND CONTROL EVALUATION www.ohsu.edu/croet/face Center for Research on Occupational and Environmental Toxicology Fatality Investigation Report OR 2008 -01-1 SPECIAL ALERT — Activation of machine controls by loose clothing, belts, or objects is a recurring contributing factor to occupational fatalities in Oregon. Mechanic killed by excavator bucket during maintenance SUMMARY A 47 -year -old mechanic was killed by an exc avator bucket during a maintenance operation. The conveyor on a portable rock crusher had stopped working, and the mechanic and equipment operators were working to raise the conveyor with the arm of a hydraulic excavator to get underneath. The mechanic sto od on the conveyor, 15 feet above the ground, to complete the task of rig ging a chain to attach the frame of the conveyor to the lifting eye on the excavator bucket Œ when the excavator boom suddenly dropped and swung, and crushed him. The excavator operat or had leaned forward for a better view of the mechanic working at the bucket, and when sitting back down the pocket of his raincoat caught on the left- side control handle for the boom, and activated it. A mechanic was standing on the conveyor of a rock crusher (arrow), rigging the frame to an excavator bucket to lift the conveyor for maintenance. The excavator boom unexpectedly swung and dropped, and crushed him. RECOMMENDATIONS Loose clothing should be avoided when operating machinery and all tools/equipment should be stored outside the cab. Eliminate or reduce worker exposure to hazard s by i nstall ing or purchas ing equipment with protective features , such as fiquick connectsfl or buil t- in anchor point s.

PAGE – 2 ============

Oregon FACE Program OR 2008 -01-1 Page 2 To aid in hazard identification and correction, e mployers should conduct and document workplace hazard assessments to include all job tasks, including maintenance, and ensure safe work procedures are followed. Use a dedicated si gnalperson in complex and limited sight lifts/picks. During lifting operations, i ndividuals working near the point of operation should reposition themselves away from pinch points and the potential swing pivot area of machinery. Employers should ensure that workers are train ed to perform best safety practices in each role during lifting operations with heavy machinery, including machine operators, signalpersons , and riggers. INTRODUCTION In January 2008, a 47-year -old mechanic was killed while standing on the conveyor of a portable rock crusher, rigging the frame to an excavator bucket. OR -FACE was notified of the incident the same day. The employer and co -workers were later interviewed by an OR -FACE invest igator. This report is based on information obtained from the interviews, and reports from Oregon OSHA and the medical examiner. The employer was a nonunion pavement recycler in business for 2 years as part of a larger business founded in 1974 . At the t ime of the incident, eight workers were employed in the field operation and three in the office. The business used heavy mobile equipment in its yard to crush concrete for recycling and subcontracted as a pavement recycler at various construction sites. The yard was an old gravel pit near the office, where a portable rock crusher operated with a folding conveyor system. A hydraulic excavator loaded material onto the in -feed conveyor. Crushed concrete or asphalt moved over the off -feed conveyor to the inpu t bin of a sorting plant, located on a platform below the crusher. The firm hired experienced operators for its heavy equipment and provided on -the -job training and observation to confirm operator skills. Daily toolbox meetings and weekly safety meetings were held. Personal protective equipment, such as hardhats and hearing and eye protection, were required in the vicinity of the rock -crushing operation. It is not known whether reflective vests or shorts were required. Fall protection was required when appropriate at job sites, but its use was not enforced at the recycler™s site. OR-FACE supports the prioritization of safety interventions using a hierarchy of safety controls, where top priorities are hazard elimination or substitution, followed by engineering controls, administrative controls (including training and work practices) , and personal protec tive equipment.

PAGE – 3 ============

Oregon FACE Program OR 2008 -01-1 Page 3 The victim was an experienced operator of construction heavy equipment and also served as a mechanic for the firm. He worked for the current e mployer for 6 months. He was unemployed 3 -4 years prior to his work there . The excavator operator had been with the firm for 5 months, and was the lead person at the yard. The operator of the rock crusher was a son of the firm™s founders and had worked the re fiall his life.fl INVESTIGATION On the day of the incide nt, the mechanic was working together with the excavator operator and a foreman to lift the off -load conveyor on the rock crusher to get underneath for maintenance. The conveyor had sto pped working, and the lifting mechanism on the conveyor did not provide sufficient power . It is not know n whether the insufficient power was a conveyor malfunction or whether it was due to the positioning of the conveyor. The task involved rigging a chai n to attach the frame of the conveyor to the lifting eye on the excavator bucket. The conveyor was then lifted by the hydraulic system on the rock crusher with assistance from the excavator . The crew had performed this operation several times in the past. The rock crusher was shut down completely. It is not known whether or not the crusher was locked and tagged out. The hydraulic excavator was placed so the boom and bucket were positioned above the rock crusher™s off -load conveyor ramp. The mechanic cli mbed onto the 4 -foot wide conveyor and stood on the end about 15 feet from the ground to rig the connection. He wore no fall -protection equipment. The victim could not reach t he lifting eye on the boom with the chain, so the excavator operator entered the cab and turned on the engine to reposition the bucket. The mechanic re mained at the end of the conveyor. The operator of the rock crusher remained at the controls of his machine, waiting to start up for the lift. After positioning the bucket, t he exca vator operator leaned out of the right cab window to get a better look toward the mechanic. The operator was wearing a rain jacket, and as he sat back down into his seat, the jacket caught on the top of the left -hand lever control for the boom arm, and act ivated the boom. The boom dropped and swung to the right, and the bucket struck the mechanic and crushed his head against the conveyor frame. The foreman saw the operator get pushed down and heard the excavator engine decelerate to idle speed. He yelled at the operator to lift the bucket. Emergency medical personnel were called and arrived within 2 minutes. The victim died at the scene. CAUSE OF DEATH: Crushing head injuries After leaning out of the right side cab window for a better view of the mechanic who was working near the bucket, the operator sat back down into his seat and his rain coat caught on the left -side control handle for the boom, causing the boom to swing and drop.

PAGE – 4 ============

Oregon FACE Program OR 2008 -01-1 Page 4 RECOMMENDATIONS/DISCUSSION Recommendation # 1: Loose clothing should be avoide d when operating machinery and all tools/equipment should be stored outside the cab. Do not operate equipment with loose clothing, a tool belt, or other items that could interfere with the operator controls. In some machines the engine may not need to be running for an operating control to result in machine movement . Several Oregon occupational fatalities in the past decade were caused by unintentional activation of a control in the cab, including a caught jacket pocket similar to this incident, a tool b elt, and a heavy object thrown onto a n unguarded foot pedal (Readers are referred to Investigation Report #s OR 2003 -15-1, OR 2004 -07-1, and OR 2007 -17-1). Recommendation # 2: Eliminate or reduce worker exposure to hazard s by i nstalling or purchasing equipment with built -in protective features , such as fiquick connectsfl and anchor points . Include fisafety, maintenance and accessfl in your evaluation process when purchasing equipment. Equipment that has designed/built in features t o reduce or eliminate exposure for maintenance staff is preferable both for safety and production , as the equipment may not need to be moved or relocated for preventive maintenance. For example , having fiquick connectsfl (or built -in anchor point s) on both ends of the conveyer designed so that an excavator operator could connect the lifting eye of the bucket to them without the assistance of a rigger would reduce the need for workers to access the raised end of the conveyer. This quick connect may need to b e added as an aftermarket attachment. Owners/operators of equipment must always follow manufactures requirements/specifications when installing aftermarket attachments and in operating equipment . Recommendation # 3: To aid in hazard identification and correction, e mployers should conduct and document workplace hazard assessments for all job tasks, including maintenance, and ensure safe work procedures are followed. Employers should conduct workplace assessments to develop safe work procedures and ensure workers are properly trained to recognize and control hazards. The manufacturer™s operational requirements and safety instructions for equipment should be included in all training and workplace assessment. To supplement hazard assessments, periodic audits or observations can be used to monitor current conditions and practices. Supervisors should use this information to provide ongoing safety feedback to workers , and to identify topics for refresher training for workers with all experience levels. Recommendation #4: Use a dedicated signalperson in complex and limited sight lifts/picks. When a worker is rigging a load to be lifted by heavy equipment, an independent pe rson with a wider view of the situation is recommended. The signalperson can make sure to be clearly visible and in constant communication with the machine operator. This can allow

PAGE – 5 ============

Oregon FACE Program OR 2008 -01-1 Page 5 the machine operator to maintain an optimal position in the cab in relation to controls. A signalperson can also warn the rigger of any shifts in the load or the machine. Recommendation #5: During lifting operations, i ndividuals working around the point of operation should reposition themselves away from pinch points and the potential swing pivot area of machinery. Workers should minimize their exposure to pinch points or the potential swing radius of machinery. Whenever possible, and especially when communication with the machine operator is interrupted, workers should back aw ay from the point of operation and /or swing radius of machinery until the next step of operations is prepared or communication with the operator is reestablished. Recommendation # 6: Employers should ensure that workers are trained to perform best safety p ractices during lifting operations with heavy machinery, including competence for machine operators, signalpersons , and riggers. In November 2010, the Occupational Safety and Health Administration implemented new safety rules for fiCranes and Derricks in Construction.fl Excavators are specifically excluded from the scope of the rules (29 CFR 1 926.1400), but like cranes, excavators are commonly used for lifting. These mandatory rules for cranes do provide useful guidance for situations present when using exc avators for lifting , as in this incident. In the future these mandated procedures for cranes could serve as the basis for safe lifting procedures for excavators. A main topic in the OSHA safety rules is a description of three crew positions relevant in th is incident: machine operator, signal person , and rigger. Employers with excavators or other equipment involved in lifting operations should ensure workers are well trained (which includes fiMake and Model Specificfl for operators ) and qualified to perform th is type of work . Crews working together should have clear understanding of the task and all signals (communication) between the signalperson and the operator. Appropriate training in lifting operations should be provided for workers at all experience lev els. Although the victim in the current case was an experienced heavy machine operator and mechanic, he had been unemployed for 3 -4 years where his access to practice and training would have been limited. Training for lifting operations should not only be Make/Model Specific for each type of equipment, it should also be task specific. Lifts will vary in complexity and detail , with most lifts not requiring any type of formal lift/pick plan. However, pre -lift plans are necessary so that a clear understan ding of the specific lift/pick is communi cated and all involved are trained, authorized , and understand their role.

PAGE – 6 ============

Oregon FACE Program OR 2008 -01-1 Page 6 In relation to this incident, several procedures are emphasized for training for each crew position: Machine operator o Equipment operator must be trained for each different specific make/model of equipment they operate. o Cabs of equipment must be clear of all tools and equipment and operators must be in appropriate attire with no loose clothing, tool belts, or other items that could interfere with operator controls (see Recommendation # 1 above ). o A clear understanding of the task to be completed must be communicated between the operator, signal person , and/or rigger . Type of signals (communication) must be clearly understood between all parties. o During operations there should be non -interrupted clear communication between the operator and the signalperson/rigger. The operator must stop the equipment and wait if communication is interrupted or not clearly understood. All individuals in the area of the equipment must know the limitations of the operator™s visibility and not approach any part of the equipment without clear communication from the operator to do so. Placement of barricades is often required. o Supervisors and machine operators may implement special safety controls , such as lock -out/tag -out procedures, during unusual or complex operations where a worker must perform a task in the line of fire of machinery that could be activated. Such procedures may follow a combination of OSHA, plant/employer , and/or manufacture recommended procedures. Signal person o Use a dedicated signal person in complex and limited sight lifts/picks (see Recommendation # 3 above) . When a worker is on the ground rigging a load to be lifted by heavy equipment, an independent person with a wider view of the situation is recommended . The signal person can make sure to be clearly visible and in constant communication with the machine operator. A signal person can also warn the rigger of any shifts in the load or the machine. OSHA rules specify a signalperson in crane operations is required wh en the point of operation or direction of travel is not in full view of the operator (29 CFR 1926.1419), or if other site -specific safety considerations make it necessary. With an excavator, lifting demands special attention. o Know and use a common system of communication. The signal person , machine operator, and ground personnel should know and agree upon a system of voice and /or hand signals. Communication with the machine operator needs to be direct and clear to ensure safety. o Individuals not directly inv olved/required for the lift/pick should be kept away from the operation.

PAGE – 8 ============

Oregon FACE Program OR 2008 -01-1 Page 8 REFERENCES National Institute for Occupational Safety and Health. 2004. Preventing Injuries When Working with Hydraulic Excavators and Backhoe Loaders (No. 2004 -107). Available online: http://www.cdc.gov/niosh/docs/wp -solutions/2004 -107/default.html Occupational Safety and Health Administration. 2010. Cranes and Derricks in Construction Final Rule. Available online: www.osha.gov/cranes -derricks/index.html Oregon OSHA. 2009. Excavations: Saf e Practices for Small Business Owners and Contractors (440 -2174). Available online: http://www.orosha.org/publications/excavationpubs.html Oregon OSHA. 2003. Excavation safety. Available online: http://www.cbs.state.or.us/external/osha/pdf/workshops/302w.pdf FOR MORE INFORMATION OR-FACE/CROET L606 Oregon Health & Science University 3181 SW Sam J ackson Park Rd Portland OR 97239 -3098 Phone 503 -494 -2281 Email: orface@ohsu.edu Website: www.ohsu.edu/croet/face/ Oregon Fatality Assessment and Control Evaluation (OR -FACE) is a project of the Center for Research on Occupational and Environmental Toxicology (CROET) at Oregon Health & Science University (OHSU). OR -FACE is supported by a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH) ( grant # 2U60OH008472 -06) through the Occupational Public Health Program (OPHP) of the Public Health Division of the Oregon Health Authority . ORŒFACE reports are for information, research, or occupational injury control only. Safety and health practices may have changed since the investigation was conducted and the report was completed. Persons needing regulatory compliance information should consult the appropriate regulatory agency.

211 KB – 8 Pages