The chain buckets facilitate the material discharge. Wheel boom hoisting gear. The wheel boom is supported by two hoisting cylinders which are hydraulically

8 pages

456 KB – 8 Pages

PAGE – 2 ============

Capacity (heaped)Specific digging force Maximum cutting height Maximum cutting depth Wheel boom length (centre Œ bucket wheel to centre of excavator) Discharge boom length (centre Œ excavator to centre of discharge chute) Maximum allowed longitudinal equipment gradient4.800 m³/h 1000 N/cm 23.0 m-2.0 m27 m32.5 m11%Bucket wheel diameter Nominal power of bucket wheel drive Number of buckets Bucket volume including annular cells Number of discharges at 85% of bucket wheel speedBelt width Service weight (depending on accessories)Maximum longitudinal leveling of superstructure10.5 m900 kW 171.05 m³ 77/min 1.8 m1.200 t8 %

PAGE – 3 ============

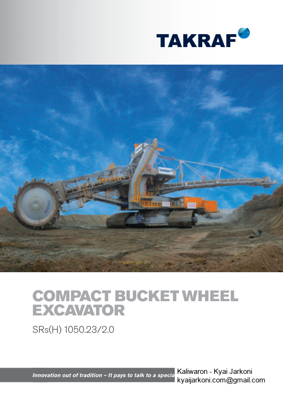

The TAKRAF SRs(H)1050 compact bucket wheel excavator can be matched with a variety of complimentary equip- ment and systems. These are chosen together with the client to suit specific mining conditions and mining methodo- logies for individual applications.Typical application: Excavation and material transfer from a mobile transfer conveyor to a bench conveyor Typical example: Excavation and cross pit sprea- ding using a transverse conveyor bridge and connected spreaderTypical example: Excavation and cross pit sprea- ding using a mobile spreader

PAGE – 4 ============

The innovative wheel boom design features a combi -nation of full-web and framework structures. This design enhances the torsional stiffness of the structure and minimizes its susceptibility to oscillation.The bucket wheel head with the powerful 900 kW TAKRAF bucket wheel gearbox was developed espe -cially for the mining of soft to medium hard materials. Equipping the bucket wheel drive with a 6 kV medium voltage motor and frequency converter has reduced transformer power loss and cable cross sections. By use of FEM calculation the buckets are designed to withstand major digging forces. The bucket design also lends itself for use in sticky material.Larger internal radii and a special cutting tool carrier height/width aspect ratio of the buckets reduce material adhesion inside the buckets. An extended bucket body minimizes the contact of the excavated material with the annular space of the bucket wheel.The chain buckets facilitate the material discharge. The wheel boom is supported by two hoisting cylinders which are hydraulically coupled using specially designed circuits. This ensures low-vibration of the SRs(H)1050, even where continuously changing material hardness in the block occurs and eases the mining of thin material layers. Each of the hoisting cylinders is equipped with a mobile piston protection system to protect them against damage.

PAGE – 5 ============

The SRs (H)1050 can be levelled horizontally thus provi -ding the ability to effectively excavate sloped seams. The hydraulic horizontal leveling system installed in the undercarriage enables longitudinal leveling of the entire superstructure by 8% in the horizontal plane.This facilitates mining of large block widths, even where the bench slopes longitudinally. The optimized design of the crawlers with 8 track rol -lers enables more efficient production, maintenance and repair of all crawler track components and a more effici – ent rate of advance of the SRs(H)1050 compact bucket wheel excavator. The shorter and more compact crawlers facilitate extre -mely economical block excavation. The latest generation of crawler girders and equalizers are integrated in an open crawler girder design which facilitates maintenance and repair of wear components (equalizers can be removed without lifting equipment). In addition to this, rockers and track rollers are constructed according to the reliable TAKRAF lifetime design. Cables are routed between the undercarriage and super-structure via a unique cable saddle that is seated in two independent pivots in the enclosed machine room of the SRs(H)1050. There they are protected against dust and dirt. This method of cable routing achieves an operational superstructure slewing range of 360° relative to the un -dercarriage via a simple, troublefree design.

PAGE – 6 ============

The SRs(H)1050 compact bucket wheel excavator is fitted with an air conditioned and shock absorbing operator™s cabin which incorporates an ergonomically designed operator™s console.Optimum operation is realized with a powerful excavation program control adapted to suit customer requirements with process visualization of all technical parameters. All material transfer points are monitored by video to ensure trouble free operation.One advantage of the TAKR AF SRs(H)1050 com-pact bucket wheel excavator compared to other de-signs lies in its maintenance-friendliness, thanks to enhanced accessibility for the installation and removal of individual components and entire modules, the reduction of wear parts and extensive use of maintenance-free bearings in the reliable TAKRAF lifetime design. The wheel boom can be supported with one of the two cylinders to ease and make safe the maintenance and repair work on the hoisting cylinders. The installation of an on-board crane (5t/ 7.5m) on the portal further facilitates maintenance and repair work.The hardened and tempered design of relevant main and individual components such as crawler links, bogies, open slewing bearing and gear rim increases their service life verifiably.The gear rims and drives for the superstructure slewing gear and loading boom slewing gear are located in the enclosed machine room of the platform and undercarri-age ring support where they are protected against dust and dirt.

456 KB – 8 Pages